1000 sets of molds are annoying? Suyun MES will help you manage

- 2021-08-13

- source: 本站

First in the spring of one year, everything is done first. Just after the Spring Festival, Zhongshan Hongpengtai Plastic Mould Technology Co., Ltd. (hereinafter referred to as Hongpengtai Plastics) immediately entered the intensive work rhythm, and fully blew the new year's charge number, from the race against the construction site to the busy In the endless workshop park, a group of people gather their efforts to roll up their sleeves and work hard for a vivid picture. In order to adapt to the era of great changes where the profit is thinner than the blade edge, Hongpengtai Plastics promotes lean production internally and introduces the "Plastic Cloud" independently developed by Guangzhou Zhonghe Internet Technology Co., Ltd. (a wholly-owned subsidiary of Borch, hereinafter referred to as Guangzhou Zhonghe). MES" Industrial Internet Project, to achieve the company's high-quality development.

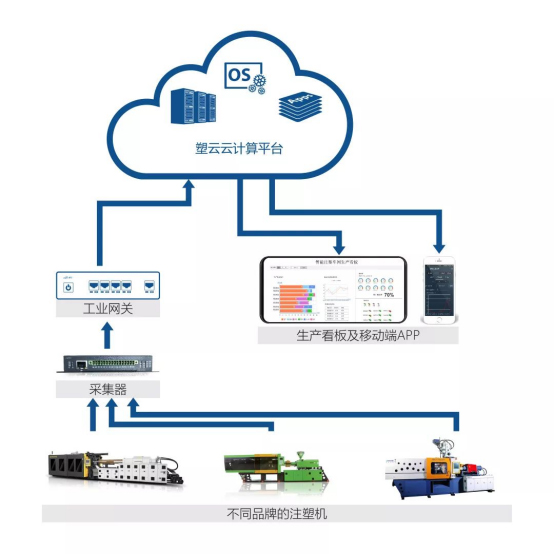

The "Plastic Cloud MES" system is suitable for the production management and equipment management of the injection molding plant. It provides an injection molding cloud platform in the industry for users of injection molding enterprises. Based on this platform, it can realize the reasonable optimization and matching of the production data of the injection molding machine, and realize the information of the injection molding production. An efficient information system for intensive management. The injection molding equipment realizes interconnection and interoperability through the "Plastic Cloud MES" on the cloud platform, forming a true injection molding industry Internet of Things. Equipment managers can view equipment status anytime and anywhere on the Internet, and collect data at the same time for use by ERP, MES and other information systems.

1000 sets of molds are annoying? Suyun MES will help you manage

Use feedback from Hongpengtai Plastic:

1. Factory has1000Multiple sets of molds. In the past, mold management and order placement required repeated meetings and discussions, several clerks scheduling and statistics , But it is still not clear. Now there are"Plastic CloudMES", mold management can be carried out according to the order situation, and production can be scheduled according to the machine. Real-time monitoring of order production is more convenient and accurate, and the production scheduling method is fully upgraded.

2. The workshop can understand the next batch of orders in advance You can make relevant preparations in advance and keep abreast of the real-time production status of orders at any time, making it easier to insert orders and adjust orders.

3. Sales staff who often travel on business can pass Plastic Cloud MobileAPPUnderstand the exact delivery date of the product.

4. Equipment and mold maintenance module is very It is easy to use. Guangzhou Zhonghe also presented LCD network TV billboards to realize the visual management of the whole plant. People can see the operation status of the injection molding workshop on the second floor, and respond to and solve some malfunctions in the workshop in a timely manner.

5. Realize paperless production in the workshop Function. At present, our order-related content has been paperless, but some projects rely on traditional paper-based records and statistics. Next, we will also include equipment management, mold management, quality management, shutdown management and other modules. Paperless function, so as to fully realize the paperless production in the workshop.

On March 10th, the "Suyun MES" system was successfully accepted at Hongpeng Taisu!