Case Sharing|A "close contact" between Mingheng Knives and Scissors and Plastic Cloud

- 2021-08-13

- source: 本站

From March 7th to 8th, Yangdong County Mingheng Knives and Scissors Products Co., Ltd. (hereinafter referred to as "Mingheng Knives and Scissors") and Guangzhou Zhonghe Internet Technology Co., Ltd. (hereinafter referred to as "Guangzhou Zhonghe") Suyun project engineers Conducted a meeting on the digital reform of injection molding production management, and completed the implementation of the plastic cloud MES system.

Mingheng Knives and Scissors are specialized in producing high-quality text Manufacturers of hardware and plastic products such as shears, lace shears, and hole punches. Its products range from cutting and cutting, perforating, leveling, polishing to cutting toughness and opening, and then to the production of injection handles, scissors assembly, and production and processing are complex. The company’s response to "digital factory management"Very important. Under the personal leadership of the company's general manager Liang and production director Liang, use plastic cloudMESThe system starts the intelligent transformation and upgrading of digital production management.

Plastic CloudMESThe difficulty of project implementation is not the complexity of the factory’s production process, but whether the company recognizes that such a modern system can improve the efficiency of the factory.

Customer said:

In the conversation, Mingheng cuts the beam I always talk about the large amount of orders customers sometimes give,"digest"< /span>It is really difficult to get up. On the one hand, I am afraid that the delivery will be delayed, and on the other hand, I am worried that the quality cannot keep up. Guangzhou Zhonghe Plastic Cloud project engineer explained that after the plastic cloudMES , The factory manager can know the running status of the machine at any time, and then can optimize the running status of the machine, increase the utilization rate of the machine, and finally increase the production capacity of the machine; Provide data support for production planning and storage period. When the engineer said that through the use of plastic cloudMES, ultimately can improve the efficiency of the factory 10%-20%, Mr. Liang’s expression suddenly became much more relaxed.

Liang said that we are injection molding micro The factory has big ambitions. I have always wanted to use the information system, but I have suffered from the MESsystems that are expensive, all in50-10010,000 yuan, or even higher, we dare not think about it. Guangzhou Zhonghe’s industrial Internet product Plastic CloudMES, at the right price, can Help us, so choose Plastic Cloud.

Plastic cloud usage feedback:

1. Managers on business trips can learn about product delivery anytime, anywhere through the plastic cloud mobile terminal Circumstances, don’t worry about emergencies in the factory.

2. The previous extensive management made the production efficiency fluctuate and it was difficult to control . Through Plastic Cloud MES, all kinds of data are truly presented to us, and refined management becomes possible.

3. The large-size Kanban provided by Guangzhou Zhonghe enables the operation of the machine and the execution of orders It's clear at a glance.

4. Through the scheduling function of Plastic Cloud MES, you can know the information of the next batch of orders in advance , Make relevant preparations for the material preparation and the advance arrangement of the machine, and you can also grasp the real-time production status of the order at any time for order insertion and order adjustment.

5. Temporarily realize paperless orders and machine production. Although it is only partially paperless, it is very convenient for our report analysis.

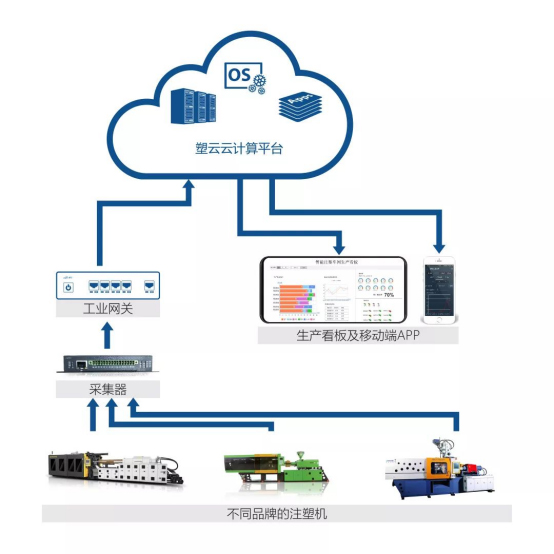

In the injection molding production management, Suyun realized the entire workshop machine networking, real-time collection of all data in the production process, so that Mingheng knife and scissors from manual extensive management to digital information management, to achieve transparent and visual management of the workshop. The Suyun MES system helps the majority of injection molding small and medium-sized enterprises to go to the cloud platform and implement digital intelligent transformation and upgrading.