Suyun assists Foshan Ruihai to open the era of digital scheduling and ordering

- 2021-08-13

- source: 本站

Foshan Ruihai Auto Parts Co., Ltd. (hereinafter referred to as "Ruihai") is a large-scale modern manufacturing enterprise integrating injection molding, metal stamping, mold development, design, production, and sales services. It is a joint venture with Guangzhou Zhonghe Internet Technology Co., Ltd. (Subsidiary of Borch, hereinafter referred to as "Zhonghe") The first batch of customers who signed a contract to purchase the Suyun MES system. After all the injection molding machines of Ruihai are connected to the Internet, Zhonghe immediately arranged for engineers to train Ruihai's production and planners on the on-line training and guidance of Suyun MES.

At 9 a.m. on March 10, after the Zhonghe MES launch engineer arrived at Ruihai, they first gave training to production managers, production team leaders, and inspection leaders in the conference room, and explained in detail the various functions and functions of Suyun MES. Operation process, and answer the questions raised by the trainees one by one. After three hours of collective training, all trainees have a basic understanding of the positioning and functions of Suyun MES, and which part they should be responsible for.

afternoon1Half and half, neutralizeMESThe on-line engineer began to provide one-to-one practical guidance to the person responsible for each link. The first step is to guide the entry of basic information of the mold. Under the guidance of the MES Director Haihuang directly exported the mold data from ERP, and then according to the plastic cloud< /span>MESThe template providedERP directly copy and paste the data on , and then batch import to Plastic CloudMES, only used20< span style="font-size: 14px;">The input of mold information was completed in minutes. In a short time, Director Huang learned the function of mold data management.

Ms. Hu, who is also responsible for product data entry, also It only took about 20minutes to import thousands of product information into Plastic CloudMESin. These data information can also be called directly in the future.

The order dispatching system is even simpler, just< /span>6Steps: 1, enter the dispatch order number;2, enter the product Number;3, select the machine;4, enter the order quantity;5< /span>, confirm the end time of the order plan;6, save the order. After only training1.5 hours, Ms. Hu, who is in charge of scheduling, can fully grasp The order dispatch function was implemented, and three work orders were dispatched. After that, she spent another half an hour learning how to insert orders, how to transfer orders and other functions.

Afterwards, neutralizeMES< span style="font-size: 14px;">Online engineers spend again1hours to teach the workshop production team leader how to start production after receiving the production scheduling plan, and how to use our quality management system when defective products are found during the inspection process.

Use only1Day time, neutralizeMES The on-line engineer completed the launch and training of MESMES in Ruihai Work. Responsible persons in each production link of Ruihai also fully grasp the plastic cloudMES Function. Ruihai’s Plastic CloudMESThe project leader Huang also expressed incredible. They are onlineERPsystem,ERPThe company’s engineers have been in Ruihai for half a year.

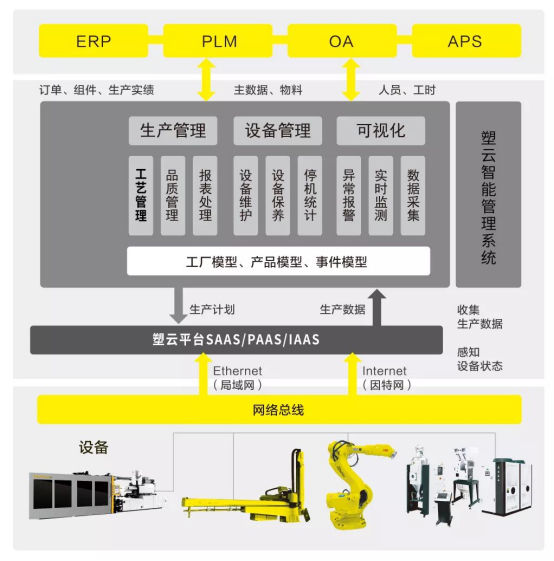

Suyun MES system is an industrial Internet cloud product independently developed by Zhonghe; it has the characteristics of low cost, fast deployment, easy implementation, and easy to use; no need to purchase professional servers, no need to recruit professional IT engineers, worry-free throughout the process, it is injection molding production Management helper. At present, more than 200 companies have chosen Suyun MES. In the future, more and more companies will choose to plastic cloud. Zhonghe will also continue to improve the functions of the Suyun MES system, and strive to create more value for customers.