Case sharing|Suyun MES allows us to achieve quality transparency

- 2021-08-13

- source: 本站

Since the first release of Suyun on August 10, 2018, tens of thousands of injection molding machines in production have been connected to Borch’s "Suyun" cloud platform. This year, the injection molding machine is expected to reach 50,000-70,000 units. This article is excerpted from the material reported by Huahui Toys (Yunan) Co., Ltd. to the local government, and truly feedbacks the changes brought by "Plastic Cloud" to injection molding production management.

I am grateful to relevant government leaders for visiting Huahui Toys (Yunan) Co., Ltd. (hereinafter referred to as Huahui) to guide the work during their busy schedule. Our company has been implementing the online plastic cloud platform for a short period of time, and here is a brief report.

Suyun MES was developed by Guangzhou Zhonghe Internet Technology Co., Ltd. (hereinafter referred to as Guangzhou Zhonghe), a subsidiary of Borch Intelligent Equipment Co., Ltd. (hereinafter referred to as Borch). Borch is a leading company in China's injection molding machine manufacturing industry. The Suyun MES developed by Guangzhou Zhonghe is an MES that truly understands the injection molding industry. It has a deep understanding of the injection molding industry and can provide the most practical functions and considerate services for us injection molding manufacturers.

First of all, we feel that Suyun MES has solved the problem of disconnection between the ERP system and the production site, and achieved quality transparency. Since the introduction of our ERP system, our company has greatly improved management efficiency and improved the entire plant's work flow. However, there are still problems in the implementation and process control of ERP plans that are not timely, but injection molding cloud MES has solved these problems for us. Specifically in:

1. Real-time order board

Through this kanban, you can not only see the real-time status of the machine (production, standby, shutdown), but also see the order information of the machine, such as product, actual output, production progress, etc.; each model can be fed back on the kanban in real time, It is very intuitive, and the kanban can be viewed directly on the mobile phone. No matter when and where, as long as you can access the Internet, you can grasp the production status through the order kanban, which is efficient and convenient.

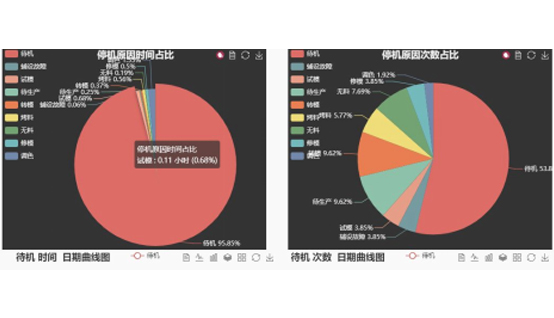

2. Real-time shutdown record

Recording the length of downtime used to be a headache. Manual recording is neither accurate nor timely. After a long time, no one cares about the length of downtime, and there is no systematic statistics on the cause of downtime. The Suyun MES can monitor the machine in real time, and any period of machine downtime will be automatically recorded by the background, and data about the length of downtime will be generated. Using the function of specifying the cause of the downtime on the tablet terminal can clearly count and analyze the cause of the downtime, which is beneficial to reduce unreasonable downtime.

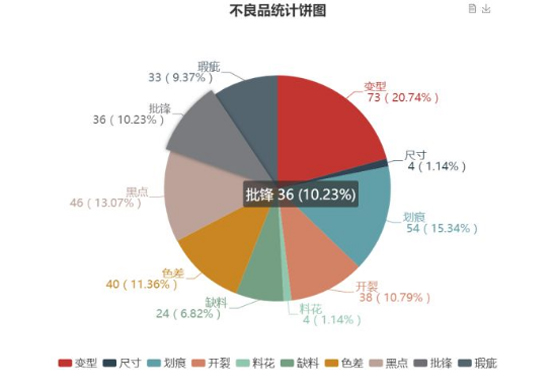

3. Entry and analysis of defective products

The mobile phone or tablet terminal can input the defective product data found on the spot at any time, without the need to input afterwards, in a timely and fast manner; at the same time, there is an intuitive statistical analysis of the bad.

Previously, the management could not know the status of the machine and the progress of the order in real time. This can easily lead to overproduction, resulting in problems such as inventory, defective products and long downtime. After the introduction of Suyun MES, these problems have been solved.

Before the introduction of Suyun MES, our company always felt that our machines were in production every day, and felt that the machines were not enough. However, after using Suyun MES to analyze the utilization rate of the machine, we found that we still have Great production potential can be tapped.