Another successful case of injection molding cloud MES-Xiamen Weibo Industry and Trade

- 2021-08-13

- source: 本站

Xiamen injection molding industry cloud platform policy briefing

Jizhonghe Injection Molding Cloud, Bochuang Second Board Intelligent Injection Molding Machine Product Promotion Conference

On September 9th, under the guidance of Xiamen Bureau of Industry and Information Technology, Borch held the Xiamen City-oriented injection molding industry cloud platform policy briefing and Zhonghe Injection Molding Cloud and Borch Second Board Intelligent Injection Molding Machine Product Promotion Conference. Hope that through this promotion will help more Xiamen injection molding companies go to the cloud platform to achieve intelligent transformation and benefit improvement.

At the meeting, Director Deng of the Xiamen Industry and Information Technology Bureau, Zhu Kangjian, Chairman of Borch, Huang Turong, Deputy General Manager of Guangzhou Zhonghe, and Wu Chongyang, Deputy General Manager of Xiamen Weibo Industry and Trade Co., Ltd., etc. shared wonderfully, making the guests feel the city of Xiamen. The sincerity of the government and Bochuang is more confident that injection molding companies can use the cloud platform to realize intelligent transformation and upgrading.

Huang Turong, deputy general manager of Guangzhou Zhonghe, introduced the injection molding cloud MES system

After the promotion meeting, the guests visited the Wibo Digital Factory and witnessed how Wibo achieved an 11.5% increase in daily processing fees within half a month after the injection molding cloud MES system was launched on August 16th!

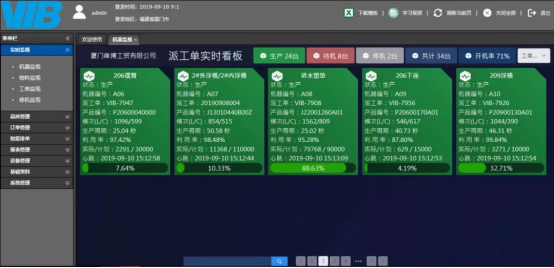

Entering the injection molding workshop, the guests were quickly attracted by the four electronic screens on the wall. These screens are the display boards of Zhonghe Injection Cloud MES system. The information displayed on the screen is the data collected on the running injection molding machine in real time. There are real-time billboards for dispatching work orders, real-time billboards for machines, equipment OEE billboards, and overall equipment utilization. The operating status of the machines and the production progress of the products are clear at a glance.

Based on these data displays, the guests eagerly wanted to know the source of the data, so they came to the injection molding machine to observe, check, understand, and inquire. Some guests took out their mobile phones, took photos and archived them; some guests conducted operational drills under the guidance of the staff.

Vice President Wu Chongyang focused on Weibo’s two sets of product incoming inspection tools, namely, the automatic size measurement system and the part weight measurement system. These two sets of detection tools can monitor and feedback abnormal data in real time. The key is that these inspection data can also be synchronized to the injection molding cloud MES system to achieve dual control of quality and cost.

Weibo Information Director Zhong Jinming introduced the original ERDS system used by Weibo, including the application of injection molding management module, integral management module and other functions, focusing on the automatic connection of data between the ERDS system and the injection molding cloud MES system. In less than two weeks, the injection molding cloud MES system and the ERDS system realized real-time data synchronization and stable operation.

Zeng Yanfen, who is in charge of production management, demonstrated on-site production scheduling based on the injection molding cloud MES system. She demonstrated how the data is automatically synchronized from the ERDS system to the injection molding cloud MES system, as well as the other use operations of the machine in the injection molding cloud MES system and the display of data billboards, which solved the mystery of the actual use of the injection molding cloud MES system to the guests. .

This promotion will use real cases to demonstrate the tangible results of the injection molding cloud MES system for injection molding companies, allowing the guests to see the hope and opportunity for the intelligent transformation and upgrading of China's injection molding industry. I believe that through this promotion, the intelligent transformation and upgrading of Xiamen's injection molding industry will usher in a new peak!