Zhonghe Injection Molding Cloud Benchmarking Client-Nansu Building Materials & Plastic Products (Shenzhen) Co., Ltd.

- 2021-08-13

- source: 本站

Nansu Building Materials Plastic Products (Shenzhen) Co., Ltd. (hereinafter referred to as "Nansu Building Materials") was established in 1994 in Xinxia Industrial Zone, Pinghu Town, Shenzhen. It covers an area of 210,000 square meters and has internationally advanced PVC extrusion production lines. More than 70, more than 100 injection molding machines, with an annual production capacity of more than 100,000 tons; 30 PE extrusion production lines, 6 HDPE winding structure wall pipe production lines, and more than 60 injection molding machines, with an annual production capacity of more than 70,000 tons; PPR extrusion production lines 6 lines, 17 injection molding machines, with an annual production capacity of 7,600 tons.

Nansu Building Materials is a natural gas pipeline supplier of China Resources Real Estate. It is also the governing unit of the Plastic Pipe Special Committee of China Plastics Association, the core member unit of the Plastic Pipe, Fittings and Valve Subcommittee of the National Plastics Standardization Technical Committee, and the China Industrial Anti-Corrosion Technology Association. Non-metallic and anti-corrosion pressure piping professional committee executive director, deputy director unit, "high-tech enterprise" of the Ministry of Construction, and also won the title of "Guangdong Famous Brand Product".

Customer management pain points

Difficult to control the production process

Product technology in the production line, Healthrow Orders, equipment, molds, etc. completely rely on manual overall planning, which is difficult to manage, easy to make mistakes, and high labor costs. In addition, the company has a large production area, a wide distribution of production lines, a variety of product types, and a wide range of equipment. Extensive equipment monitoring cannot quickly respond to the need for urgent orders.

Difficult to trace the cause of defective products

In the production process, it is difficult to count and analyze the causes of defective products, and it is impossible to effectively trace the production parameters or equipment. Production optimization relies on manual experience.

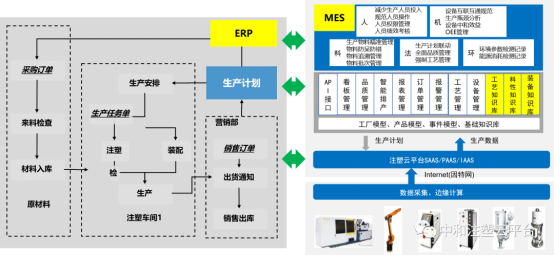

Injection Cloud MES Solution

Guangzhou Zhonghe Internet Technology Co., Ltd. and Huawei Cloud provided Nansu Building Materials with the overall solution of the injection cloud production management MES system and IoT equipment, which realized the whole production process monitoring, remote monitoring of production equipment information, product quality tracking monitoring, and Retrospective. The system has strict user authority distribution and password management to ensure the security of the system.

Program highlights

Multi-device co-management

On the basis of Internet of Things for injection molding machine equipment, extruder equipment also realizes network management. Different equipment in different plants can be managed together on one system, and the real-time production status of injection molding machine equipment and extruder equipment can be mastered in one hand. Information has greatly improved equipment production efficiency.

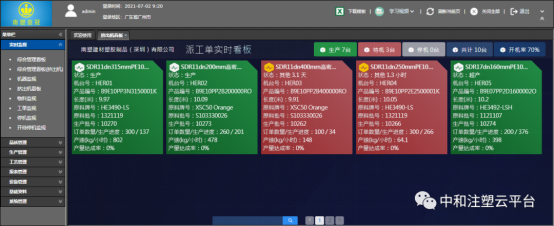

-Extruder real-time kanban interface diagram-

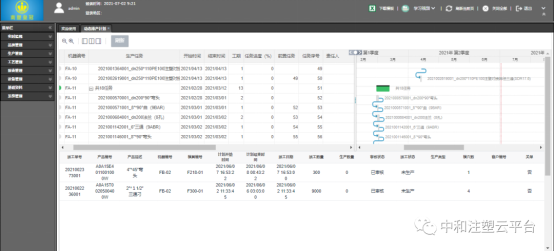

Simple and flexible scheduling

The dynamic production scheduling plan responds more flexibly to the long-term whole plant production scheduling plan, eliminates the waste of improper scheduling, comprehensively improves resource utilization, and responds to urgent order insertion requirements more easily and simply, and achieves more efficient production in a more reasonable way.

-Dynamic scheduling interface-

Accurate management of production orders

Overall production management, centralized management of product information, production batches, production progress and other information, helps companies efficiently trace the causes of defective products, optimize equipment process parameters in time, increase product yield, and reduce raw material waste.

-Integrated management kanban interface diagram-

Visualization of the production process

Make the production process of workshop equipment transparent, view the production status of equipment anytime and anywhere, and view and export data statistics and analysis with one click. The visualized utilization rate OEE allows equipment managers to grasp the working status of the machine in real time, and expose abnormal events in the production process. , Digital production has effectively improved the problem of relying on manual experience for production optimization.

-Interface diagram of real-time kanban board for dispatching work orders-