Zhonghe assists Xiamen Bejet's intelligent transformation and upgrading

- 2021-08-13

- source: 本站

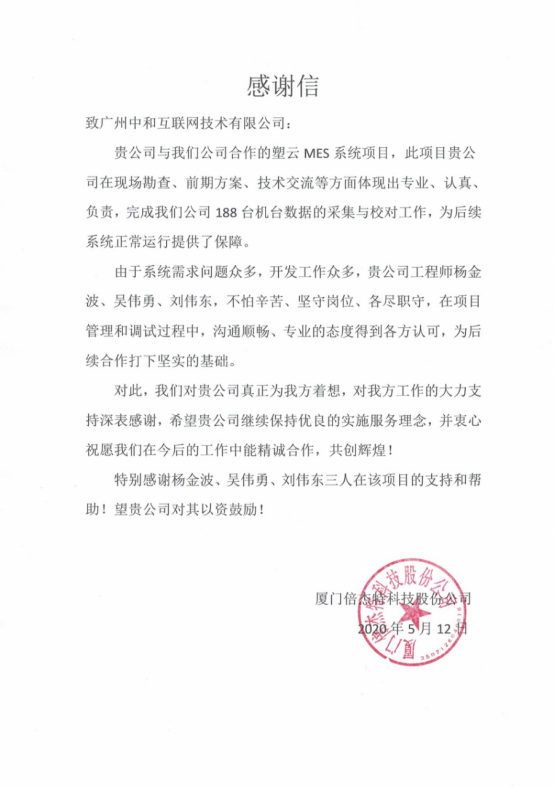

On May 12, Borch’s subsidiary Guangzhou Zhonghe Internet Technology Co., Ltd. (hereinafter referred to as “Zhonghe”) received a letter of thanks from Xiamen Beijiete Technology Co., Ltd. (hereinafter referred to as “Xiamen Beijiete”). Thanks to Zhonghe Injection Molding Cloud MES for assisting Xiamen Bejet in the intelligent transformation and upgrading of factory plastic machines. The letter also commended the three Zhonghe engineers Yang Jinbo, Wu Weiyong, and Liu Weidong for their dedication and dedication, and thanked them for their support and help.

In September 2019, Zhonghe Company sent an injection molding cloud project manager and training lecturer to Xiamen Beijiete customer site for project follow-up and training. During this period, they have been in close contact with customers, assisting customers in the promotion and use of the MES system throughout the company, and completed the company's 188 machines (including injection molding machines and hydraulic presses) on the cloud platform.

In order for the system to be more compatible with the operating mode of the client company, Zhonghe R&D engineers Yang Jinbo and Wu Weiyong went to the customer site to conduct surveys and understanding, and then opened up the Kingdee ERP system and the MES system used by the customer to achieve data capture and return to form data Of a closed loop. Monitor and understand the data and status of each link in the whole process, from work order delivery to machine production, one-click reporting to the warehouse at the end of production; from the previous manual records and paper reports to the current intelligent monitoring and one-click simplicity operate. The R&D engineers of Zhonghe also specially developed a hydraulic press data collection program for the customer's urea-formaldehyde workshop, realized the first hydraulic press platform on the cloud, and completed the company's 188 machines (including injection molding machines and hydraulic presses) on the cloud platform.

From the beginning of the workshop’s traditional manual operations and manual statistics and reports, Xiamen Beijiete has realized the intelligent transformation and upgrading of the factory, and the whole process of production management is transparent. You can check the production situation in the workshop anytime and anywhere, and put the abnormal situation of the workshop first. Send alarm information to the person in charge at time, intelligent generation of all-round statistical reports, online viewing at any time, and one-click download for reporting.

In the process of the whole project, Zhonghe obtained the full recognition and support of Xiamen Bejet, and worked hand in hand to build Xiamen Bejet into an intelligent injection molding factory.

Lead the leaders of Xiamen Bejet to visit Xiamen Weibo

Discuss with Xiamen Bejet Leadership Meeting

Training Xiamen Bejet personnel how to operate the injection molding cloud intelligent system

postscript:

We are grateful for the customer's affirmation and support, and thanks to the silent contributions of the three engineers Yang Jinbo, Wu Weiyong, and Liu Weidong. The people of Borch will "take the customer as the center and realize the happiness of customers and family".