KPI assessment board

- 2021-08-13

- source: 本站

Shanghai Chenguang Stationery Co., Ltd. (hereinafter referred to as "Morning") is committed to providing comfortable, interesting, environmentally friendly, and cost-effective stationery products, allowing people to enjoy the process of use and inspiring users' creativity. Products cover all kinds of writing tools, correction tools, erasers, rulers, glues, painting materials, books, bags, PP, desktop supplies, electronics, pencil sharpeners, financial and administrative supplies, puzzles And other product areas. Ranked first in the domestic stationery industry. In August 2019, it joined hands with Guangzhou Zhonghe Internet Technology Co., Ltd. (a subsidiary of Borch, hereinafter referred to as "Zhonghe") to realize intelligent transformation and benefit enhancement.

Chenguang Shang Injection Cloud·Front

As a domestic stationery giant, Chenguang also has difficulties in production and execution. Before this project was launched, I found that customers had these difficulties in the production and execution level during the conversation with Chenguang:

1. It is impossible to know the boot rate of each machine every hour in real time;

2. The machine boot rate of each shift requires manual statistics, which requires a lot of work;

3. It is not possible to know the production status of each machine in real time, it needs to be understood on site, and the efficiency is not high;

4. The abnormal machine cannot be quickly understood and the response time is long;

5. I can’t know which machines have the longest downtime every day;

6. The execution process of the ERP production plan cannot be monitored in real time;

Morning on the injection cloud·post

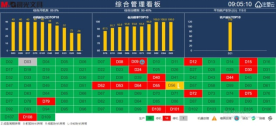

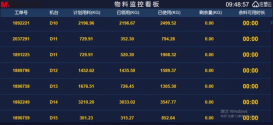

For Yu Chenguang’s problem that it is difficult to count the machine operating rate, Zhonghe Internet Technology Co., Ltd. specially developed Shanghai Chenguang’s shift kanban, integrated management kanban, production switching kanban, and material monitoring kanban to solve the problem that customers cannot understand the machine accurately and in real time. The availability issue of this shift board helped Chenguang transform from traditional manual work to brand new system work.

【上海晨光定制化看板】↓

Value gain

Guangzhou Zhonghe helps Shanghai Chenguang realize the transformation and upgrading of intelligent manufacturing, reducing costs and increasing efficiency

1. Comprehensive utilization rate of equipment increased by 20%

2, productivity increase 15.2%

3. Increase the punctual rendezvous rate of orders by 10%

4. Increase the accuracy of equipment scheduling by 30%

5. Downtime for mold failure and waiting for materials has been reduced by 15%

The road to neutralization upgrade

Through this customized Kanban for Chenguang to solve the problem of difficult statistics of machine operating rate in the injection molding industry, the journey of Zhonghe in the future will be towards providing chain connections, calculations, One-stop industrial Internet platform products and services such as innovation, application, and artificial intelligence are committed to helping injection molding companies realize intelligent transformation and upgrading.