Committed to becoming a pioneer in the 40 construction field of the injection molding industry, rooting in the plastics and plastic machinery industry, providing one-stop connectivity, computing, innovation, application, artificial intelligence, etc. for the digital, networked, and intelligent upgrade and transformation of the global plastics manufacturing industry Industrial Internet platform products and services.

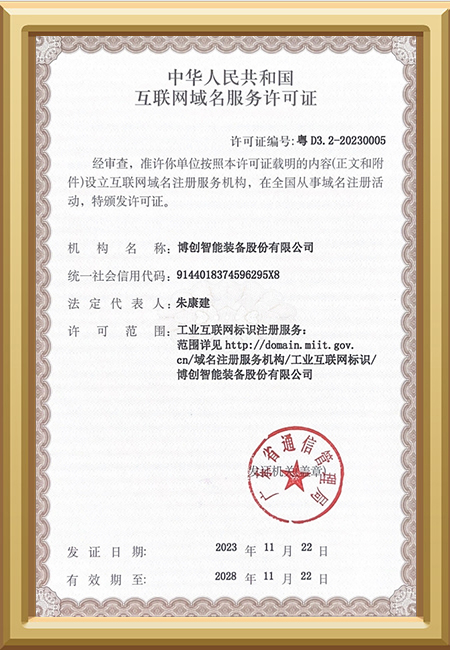

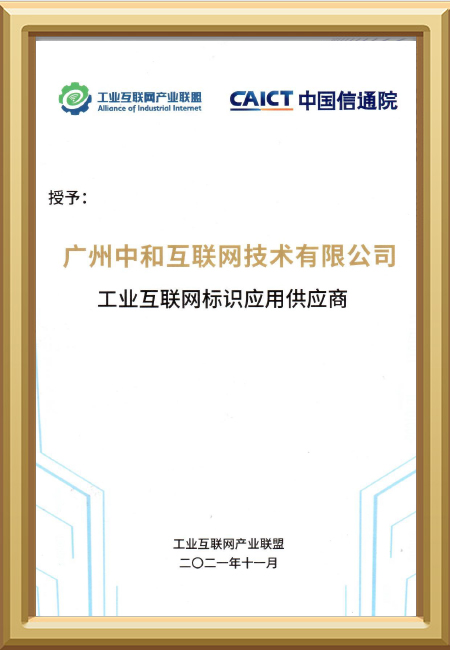

Guangzhou Zhonghe Internet Technology Co., Ltd. is a wholly-owned subsidiary of Borch Intelligent Equipment Co., Ltd. It is committed to becoming a pioneer in the field of plastic injection industry 4.0 construction, taking root in the plastics and plastic machinery industry, and contributing to the digitalization and network It provides one-stop industrial Internet platform products and services such as connection, computing, innovation, application, and artificial intelligence. As the industrial Internet big data center and the national identification analysis second-level node construction unit of the injection molding industry, Zhonghe has accumulated more than 300 industrial enterprises and realized the interconnection of more than 10,000 injection molding machines. The number of logo registrations exceeded 1.8 billion, and the monthly analysis volume Over 100,000 times.

Guangzhou Zhonghe teamed up with Huawei and other ecological partners to create a three-dimensional integrated product of injection molding cloud 10T + MES + artificial intelligence knowledge base, and successfully implemented Shanghai Chenguang (the leader in the stationery industry), Jiangsu Sanxiao Kejie, Guangdong Wanxing Toys, Xiamen Beijiete (Sanitary Ware) ) Benchmark application projects such as Xiamen Weibo and Guangzhou Zhongxin Auto Parts.

In 2020, Zhonghe Company took practical actions to join the front line of epidemic prevention and control, and was successfully selected as the first batch of Guangdong Industrial Internet Epidemic Prevention and Control Products China Industrial Technology Software Industry Alliance to help companies resume work and resume production. Recommended Industrial Internet APP products.

Injection Cloud History

Development HistoryProposed the transition from "manufacturing" to "intelligent manufacturing" and conceived an injection molding flexible smart factory

In the same year, "Injection Molding Industry 4.0" technical seminars were held in 15 cities across the country, including Hefei, Changzhou, Wenzhou, Chongqing, and Guangzhou.

PHM injection molding machine's life and health big data platform released and launched the first "unmanned high-speed injection molding production line" in the injection molding industry, exported to Florida, USA

Guangdong Industrial Internet Industry Alliance Member Huawei Cloud Excellent Solution Partner, Telecom’s first batch of 5G commercial customers

April 2010

June 2013

March 2015

August 2016

February 2017

September 2018

February 2019

August 2020

Selected into the National 863 Engineering Machinery CNC Generation Technology Plan, and the first to cooperate with a giant in the home appliance industry to implement a plastic smart factory that uses lean production to drive automation, informatization, and digitization"

The industry takes the lead in implementing the interconnection of injection molding equipment, and the interconnection of unmanned production lines between injection molding machines and mold temperature units, chillers, dryers, manipulators, etc., and the introduction of unmanned injection molding production lines at the 2016 Adsale Exhibition

"Plastic Cloud" PlasCloud officially launched operations, helping thousands of enterprises to go to the cloud and re-establish the national technology plan for the deep integration of artificial intelligence and injection molding equipment

Selected as the first batch of Guangdong Industrial Internet Epidemic Prevention and Control Products Awarded Huawei Cloud Kunpeng Certification

Honor

Honor

Service Hotline

Follow WeChat